Introduction of Biogas generator

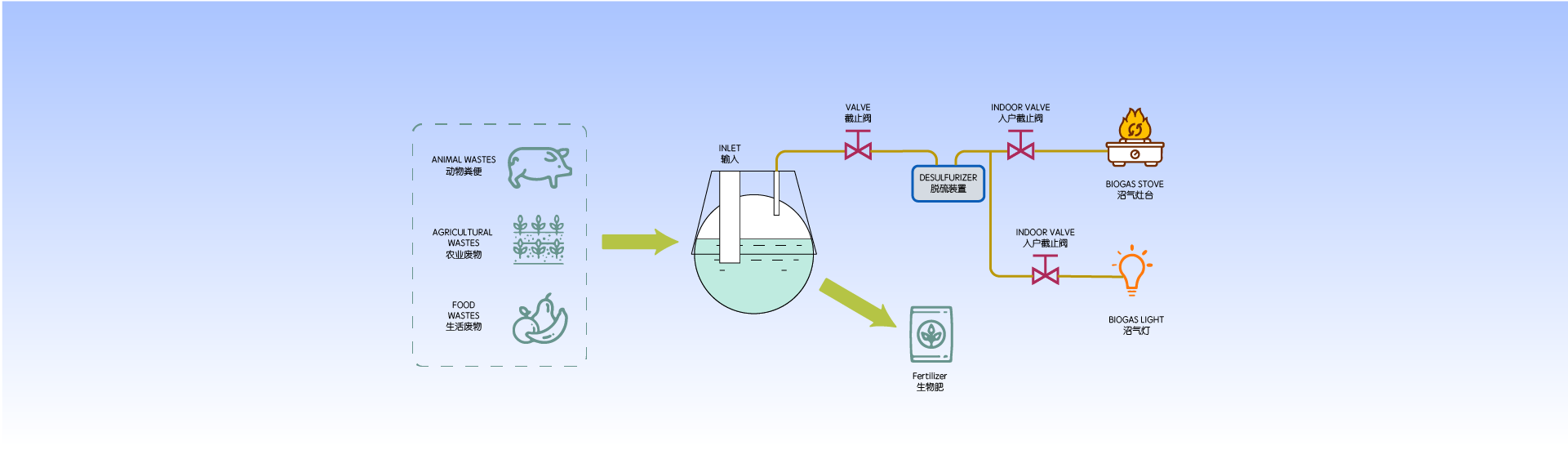

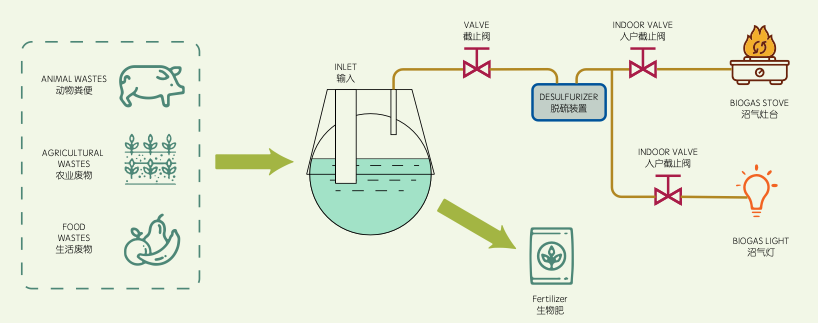

Biogas solutions offer rural villagers an economical approach that combines organic waste treatment with the provision of clean biogas energy.

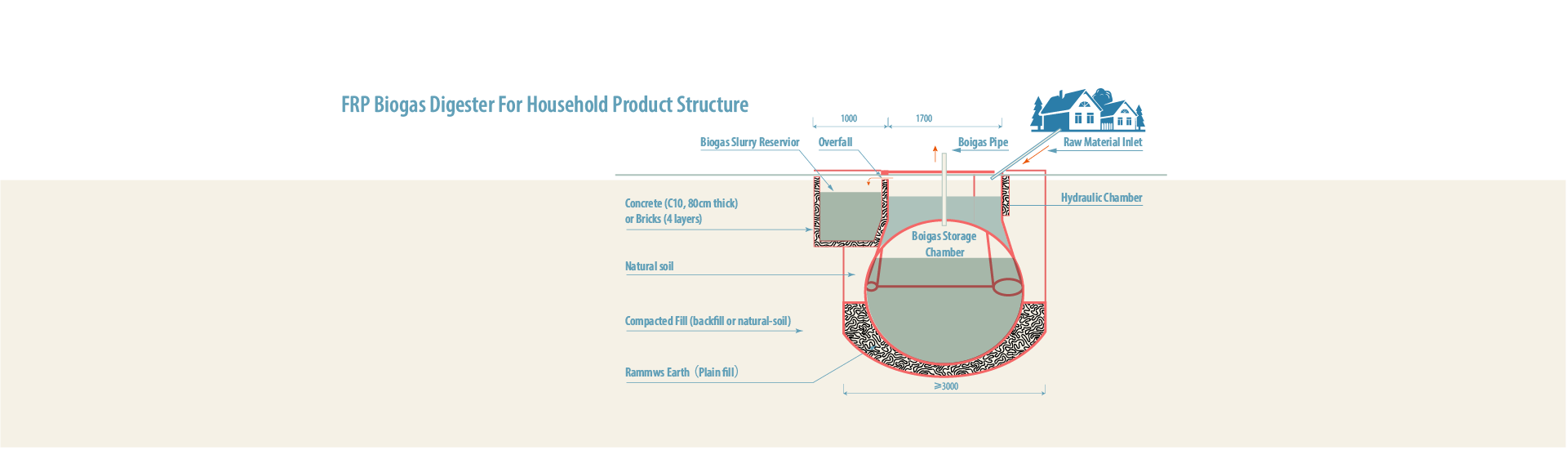

Fiberglass Reinforced Plastic (FRP) biogas digesters are hydraulic biogas systems that facilitate the automatic circulation of biogas slurry and residue. The slurry and residue from the hydraulic sealing chamber can return to the digestion chamber through a reflux pipe connected to the upper biogas storage chamber. This allows the biogas slurry to undergo repeated fermentation, participating in the decomposition of fermentable materials. As a result, the fermentable substances in the floating water are fully broken down without forming a crust.

The product is designed for easy disassembled transportation, household assembly, and underground installation.

Easy to install

Durable, lasting 30-50 years

Highly reliable

Environmentally friendly